We Deliver Exceptional Custom Foam Components to Enhance Your Success

As a leading manufacturer of fabricated and molded foam components for a wide range of North American industries, we have earned a stellar reputation for our exceptional expertise, advanced solutions, unwavering reliability and consistent product quality.

At Custom Foam Systems, we:

- offer proven polyurethane solutions for a diverse range of operator comfort padding, steering wheels, handles, packaging, specialty seating, and NVH foam components.

- manufacture durable, comfortable products with automotive OEM class A cosmetic properties.

- are ISO 9001:2015 registered and FDA Compliant.

- meet FMVSS302 flammability.

- offer advanced product development that embraces Advanced Product Quality Planning (APQP), Production Part Approval Process (PPAP), Failure Mode & Effect Analysis (FMEA) to ensure manufacturing success on the first production run and every run after.

Product Applications

Custom Packaging & Dunnage

Features:

- Full service packaging and dunnage solutions available

- Polyurethane and polyethylene materials available in a wide range of densities, compressions and colors to meet your unique needs

- Polyether, polyester, cross-linked, non cross-linked, anti-static, and anti-scratch

- One-way, one-time solutions to large scale returnable programs available

- Customized packaging solutions for electronics, tools, foods, auto parts, breakables, presentation cases and more

Materials/Specs:

Motor Sport Vehicle Foam Comfort Pads

Features:

- Seats, grab handles, steering wheels, knee pads, and passenger pads with superior durability and comfort

- Excellent foam performance; UV resistant, water resistant, suitable for hot and cold environments, cleanable, mildew resistant, and antimicrobial

- Advanced solutions to unique challenges of polyurethane components used on motor sport vehicles

Materials/Specs:

Operator Foam Comfort Pads

Features:

- Ergonomically friendly pads and handles increases productivity

- Chemical resistant and durable

- Consistent performance in high use and aggressive environments

- Increases safety of operators for fewer injuries

- High density, high durometer, high impact, cut resistant, pick and peel proof

- Antimicrobial, chemical resistant, cleanable

- Custom shaped, color matched and textured

Materials/Specs:

RV Cushions

Features:

- Versatile range of foam materials, densities and compressions to form perfect solutions

- 40 years of experience in RV industry

- Large part processing capability to maximize modularity and space

- Innovative weight reducing solutions

Materials/Specs:

Specialty Seating

Features:

- Tight tolerance/specifications and consistently high quality solutions for uniquely shaped and thin profile seating applications

- High density, low weight, high performance

- Manufactured with additional features that allow of ease and consistency of covering and upholstery such as Velcro strips and snaps through holes

Materials/Specs:

NVH Foams

Features:

- Molded and fabricated foams to insulate from a motor’s inherent noise, vibration and harshness

- Scientifically developed foam solution perfect for wide temperature range and wet/moist environments

- Cosmetic appearance provides long-term value

Materials/Specs:

Our Custom Foam Manufactured Components are Utilized in Products for these Leading Companies

Success Story

A noisy outboard motor. Complex NVH foam components.

ISKIN technology pushed further than ever before.

Manufacturing Capabilities

Our manufacturing facility is ideally suited for medium to high volume production runs and can be scaled up or down to meet your individual needs. Being highly adaptable and responsive is just one way we continue to build long-term customer relationships year after year.

Materials Technology

-

Polyether Polyurethane Foam (PU)

- Meets FMVSS302 flammability standard

- Capability to formulate foam grades to meet OEM specifications

- Polyethylene Foam (PE)

- Visco-Elastic Memory Foam

- Pressure Sensitive Adhesive (PSA) backed Polyurethane Foam

- Meets automotive VOC emissions standards

- Molded Flexible HR Foam

- Molded Integral Self Skinning Foam (ISKIN)

- Meets automotive standards for durability and stain resistance

- Color matched to OEM specifications

-

Visco Elastic Integral Skin Foam

- Molded Gelfoam

- NVH Foam

- High and low density

Molded & Fabricated Processes

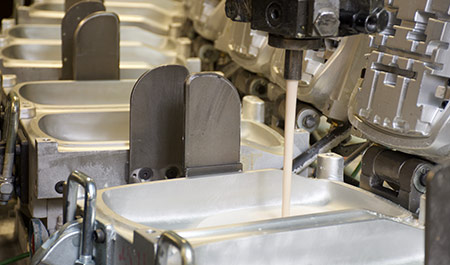

- Five reaction injection molding cells for range of material options

- Complete line of molded polyurethane chemistries tailored to program specifications

- Automated CNC shape cutting

- Horizontal and vertical CNC cutting equipment

- Precision die-cutting cells

- Multi-component assembly with advanced water-based adhesive

Certifications & Qualifications

- Qualified Tier 2 and 3 OEM supplier for North American manufacturers with proven track record of performance

- Registered to ISO 9001:2015 and FDA compliant

- World-class lean manufacturing systems modelled after Toyota’s Production System (and Hoshin Kanri approach) with the goal of reducing waste and increasing value for customers

- Embracing Advanced Product Quality Planning (APQP), Production Part Approval Process (PPAP), Failure Mode & Effect Analysis (FMEA)

- Hourly tracking of production output and quality to meet targets and drive continuous improvement

- Daily pre-shift and production performance meetings with all team members

Process. People. Success.

Our continuous improvement and quality processes demonstrate how adaptable, resourceful, and highly skilled are staff is. Every team member is engaged and committed to contributing to enhancements that will accomplish the goal of making your product development and manufacturing program the greatest success it can be.

There is no greater compliment than being chosen as your partner. We are committed to building a long-term relationship and meeting your needs at the level of excellence that exceeds your expectation.

Get Expert Help with Your Manufacturing Project

Paul MacDonald

Technical Sales RepresentativeFabricated Products

519-748-1700 ext. 250

1-800-804-3626