We Have Just What You Need in Foam Material

We offer a full arsenal of polyurethane foam material that can be skillfully fabricated and/or molded by our experienced manufacturing team to meet your most demanding requirements.

CFS has also pioneered the development of a specialized material called Gelfoam; a unique and innovative material that features a tough, texturized outer skin with an intriguing soft touch and slow recovery feel.

Given our volume and strategic partnerships with key suppliers, our raw material costs are competitively priced. Using a proprietary inventory management system, we always have what’s needed on-hand, in addition to back-up provisions so we’re ready to respond to whatever comes our way.

A complete list of the material technologies we work and their properties can be found below.

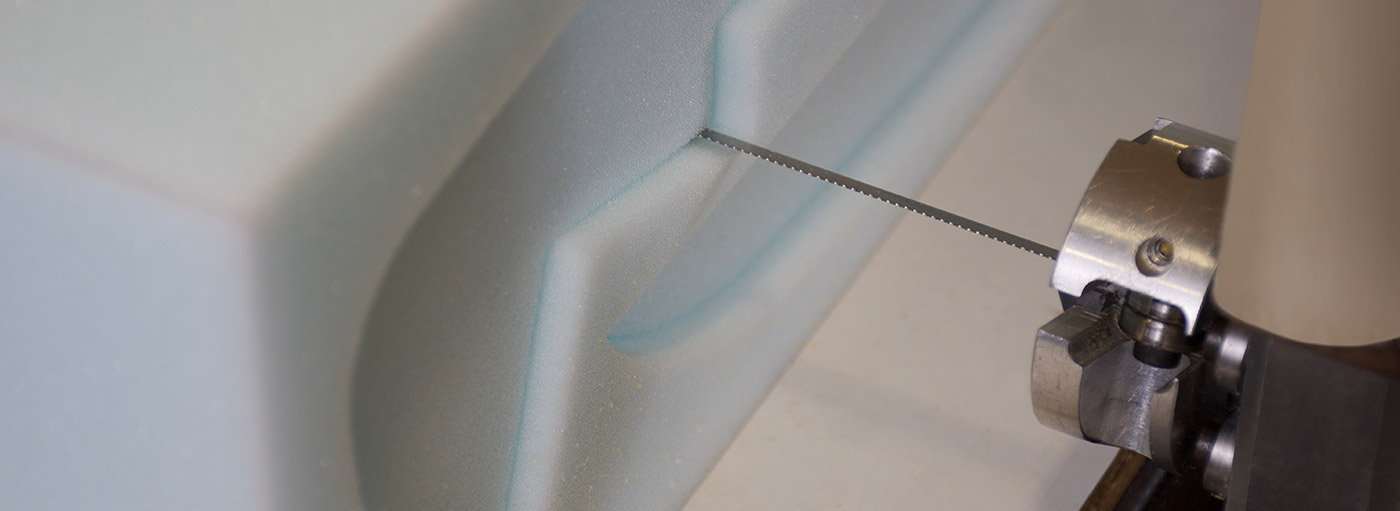

Fabricated Materials Technology

-

Polyurethane Foam (PUR)

- 1.0 – 2.8 PCF density range

- 10 – 120 IFD compression range

- California 117-2013 flammability

- FMVSS302 flammability

- Reach & ROHS compliant

- Anti-microbial grades available

- Capability to formulate foam grades to meet OEM specifications

-

Polyethylene Foam (PE)

- Cross-linked & non cross-linked

- Cross-linked meets FR standards (UL94 HF-1; FAR 25.853; FMVSS302)

- 1.5 – 6.0 PCF density range

- Multiple colors & compressions

- Brand names like Zote, Microcell, Ethafoam, and Volara

- Reach & ROHS compliant

- Pink anti-static

- Anti-scratch

- Visco-Elastic Memory Foam

- 2.0 – 6.0 PCF density range

- 9 – 25 IFD compression range

- California 117 flammability

- FMVSS302 flammability

- Reach & ROHS compliant

- Anti-microbial grades available

- Excellent performance at wide temperature ranges

-

Pressure Sensitive Adhesive (PSA) backed Polyurethane Foam

- 1.2 – 2.5 PCF density range

- 20 – 80 IFD compression range

- 2.0 – 5.0 mil adhesive

- Acrylic transfer tape

- High tack & peel strength

- Customized material solutions to meet OEM specs

- FMVSS302 flammability

- Reach & ROHS compliant

- Meets automotive VOC emissions standards

-

Sewn Covers

- Wide range of antimicrobial, regular fabrics & vinyls

- 16CFR 1632 compliant

- 16CFR 1633 compliant fire barrier

- Low MVT polyester & nylon mattress cover fabrics

- 2-way & 4-way stretch polyester fabric

- Made of waterproof, non-allergenic vinyl

- Grip-X anti-slip vinyl for padded fall mat

- FDA compliant

- Standard hospital bed, plus custom sizes

- Precision accuracy cutting & sewing

- Excellent durability and comfort covers

- Designed to keep mattress clean & protected from dust, incontinency, odors & stains

- Protects entire mattress/cushion from liquid spills & soiling

- Available in zippered & contoured designs

- Stitched, double stitched & RF welded

- Durable, waterproof, antibacterial & bed-bug proof

- Machine wash/dry

- Virox cleaning compatible

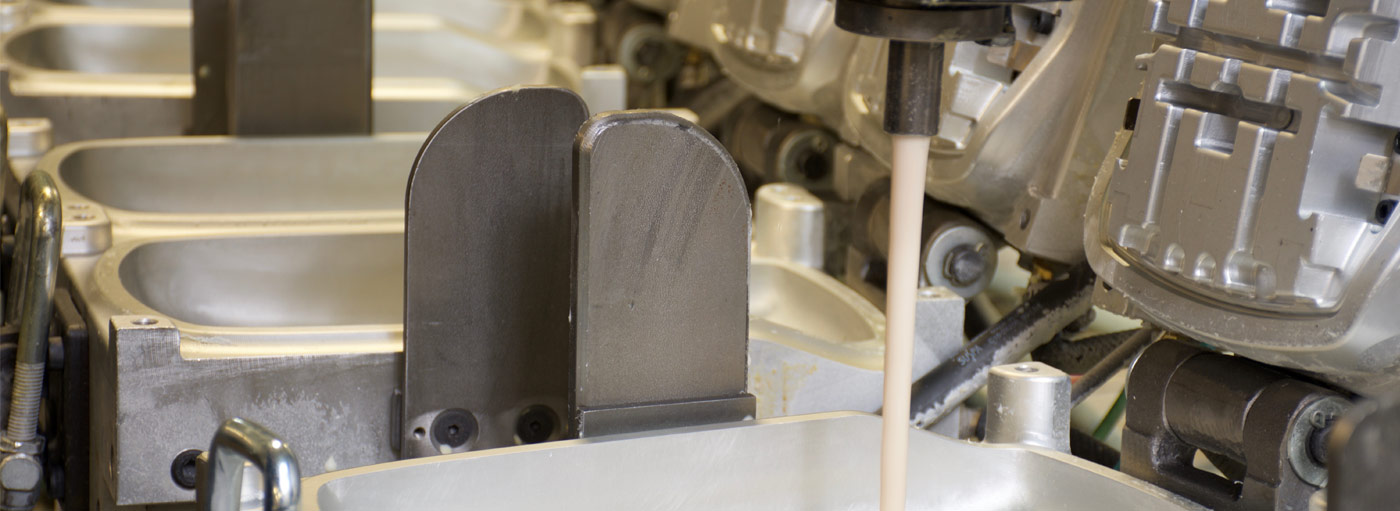

Molded Materials Technology

-

Molded Flexible HR Foam

- MDI based

- Water blown (US EPA SNAP compliant)

- 2.8 – 5.0 Pcf density range

- 20 – 60 ILD @ 25% compression range

- FMVSS302 flammability

- California 117-2013 flammability

-

Molded Integral Self Skinning Foam (ISKIN)

- Alternative Blowing Agent (US EPA SNAP compliant)

- 15 – 30 Pcf density range

- 16 – 65 Shore A Durometer range

- FMVSS302 flammability

- Meets automotive OEM standards for durability & stain resistance

- Antimicrobial to healthcare standards

- Successfully disinfect ISKIN surfaces with Virox, alcohol & bleach solutions

- Color matched to OEM specifications

- In-mold coated for enhanced UV stability & gloss consistency

- NVH Foam

- 3.4 – 15 Pcf Density Range

- Molded & fabricated solutions customized for your specific needs

- FMVSS302 Flammability

- Molded & fabricated foams offer insulation from a vehicle’s inherent noise, vibration & harshness (NVH)

- Scientifically developed foam solution perfect for wide temperature ranges in dry, wet or humid environments

-

Visco Elastic Integral Skin Foam (ISKIN MEMORY FOAM)

- Water blown (US EPA SNAP compliant)

- Molded Gelfoam

- 18 – 22 Pcf density range

- Gelfoam is a unique & innovative material (pioneered by Custom Foam Systems) that features a tough, texturized outer skin with an intriguing soft-touch and slow recovery feel

- Antimicrobial, anti-static, cut resistant, and no messy gel leaks

Get Expert Help with Your Manufacturing Project

Paul MacDonald

Technical Sales RepresentativeFabricated Products

519-748-1700 ext. 250

1-800-804-3626