We Specialize in Custom Polyurethane Automotive Foam Components

As a leading automotive foam supplier, CFS has earned a stellar reputation for its exceptional expertise, advanced solutions, unwavering reliability and consistent quality.

At Custom Foam Systems, we:

- have more than 40 years of polyurethane foam component development and manufacturing experience.

- offer world-class lean manufacturing modelled after Toyota’s Production System and Hoshin Kanri approach

- are ISO 9001:2015 registered and FDA compliant.

- embrace APQP, PPAP and FMEA.

- are an OEM qualified Tier 2 and 3 automotive foam component supplier throughout the US, Canada and Mexico.

- offer medium and high volume manufacturing capacity to service multiple programs.

Product Applications

FOAM HEAD RESTS

Features:

- Molded shape design freedom

- Proprietary foam system that meets latest requirements for safety, comfort, function, durability and weight

- Excellent cosmetic appearance harmonizing with color, texture and a seamless finish

- Special substrates can be molded in for added customization or attachment (i.e. armatures)

Materials/Specs:

FOAM CONSOLE PADS

Features:

- Molded foam directly onto substrate; ready to assemble for maximum efficiency

- Exceptional product performance provides comfort and durability

- Precision manufacturing ensures consistency and reliability

- Excellent cosmetic appearance harmonizing with color, texture and a seamless finish

- HR foam in-place consoles for leather or vinyl covering

Materials/Specs:

FOAM SEAT TOPPER PADS

Features:

- Open cell die-cut foam with and without PSA backing for superior comfort and fit

- Extensive range of customized material solutions tailored to each program

- Utilizing our proprietary precision die-cut solution to minimize handling and cost

- Outstanding PSA performance from initial tack to post adhesion performance for long term durability

Materials/Specs:

STEERING WHEEL HORN PADS

Features:

- Molded integral skin foam directly onto substrate; ready to assemble for maximum efficiency

- Safety through reliable performance, precision and accuracy

- Meets the highest industry standards for Class A surface finish

Materials/Specs:

NVH FOAMS

Features:

- Molded and fabricated foams offer insulation from a vehicle’s inherent noise, vibration and harshness (NVH)

- Scientifically developed foam solution perfect for wide temperature ranges and wet/moist environments

Materials/Specs:

OTHER INTERIOR FOAM PARTS

Features:

- Molded integral skin components offer an extraordinary and luxurious soft touch feel

- Excellent adhesion to substrates ensures lasting quality and a precise fit

- Class A cosmetic appearance harmonizing with color, texture and a seamless finish

Materials/Specs:

Our Custom Foam Manufactured Components are Utilized in Products for these Leading Companies

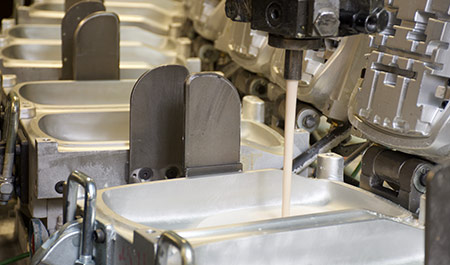

Manufacturing Capabilities

Our manufacturing facility is ideally suited for medium to high volume production runs and can be scaled up or down to meet your individual needs. Being highly adaptable and responsive is just one way we continue to build long-term customer relationships year after year.

Materials Technology

-

Polyether Polyurethane Foam (PU)

- Meets FMVSS302 flammability standard

- Capability to formulate foam grades to meet OEM specifications

- Polyethylene Foam (PE)

- Visco-Elastic Memory Foam

- Pressure Sensitive Adhesive (PSA) backed Polyurethane Foam

- Meets automotive VOC emissions standards

- Molded Flexible HR Foam

- Molded Integral Self Skinning Foam (ISKIN)

- Meets automotive standards for durability and stain resistance

- Color matched to OEM specifications

-

Visco Elastic Integral Skin Foam

- Molded Gelfoam

- NVH Foam

- High and low density

Molded & Fabricated Processes

- Five reaction injection molding cells for range of material options

- Complete line of molded polyurethane chemistries tailored to program specifications

- Automated CNC shape cutting

- Horizontal and vertical CNC cutting equipment

- Precision die-cutting cells

- Multi-component assembly with advanced water-based adhesive

Certifications & Qualifications

- Qualified Tier 2 and 3 OEM supplier for North American manufacturers with proven track record of performance

- Registered to ISO 9001:2015 and FDA compliant

- World-class lean manufacturing systems modelled after Toyota’s Production System (and Hoshin Kanri approach) with the goal of reducing waste and increasing value for customers

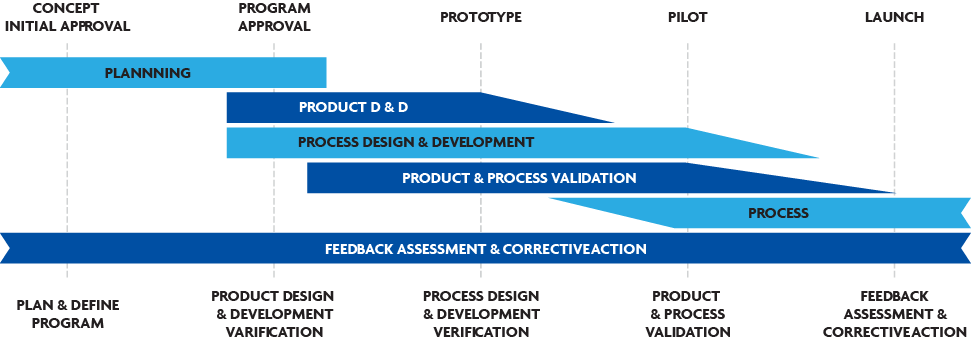

- Embracing Advanced Product Quality Planning (APQP), Production Part Approval Process (PPAP), Failure Mode & Effect Analysis (FMEA)

- Hourly tracking of production output and quality to meet targets and drive continuous improvement

- Daily pre-shift and production performance meetings with all team members

Custom Foam Product Development APQP & PPAP

Exactly what you need, when you need it

Reputation is everything. We are relentlessly committed to manufacturing excellence because your reputation, as well as our own, relies on it. Our proven production system and stringent standards allows us to meet the most demanding needs of the automotive industry; ensuring your components are manufactured on-spec, on budget and delivered exactly when you need them.

Talk to a Foam ExpertGet Expert Help with Your Manufacturing Project

Paul MacDonald

Technical Sales RepresentativeFabricated Products

519-748-1700 ext. 250

1-800-804-3626